HISTORY

OF BRAKES AND LAWS

·

1925

MODEL T

·

1929

MODEL A

·

steel

rod going to each wheel, apply brakes manually

·

hydraulic

system, started with one master cylinder for all 4 wheels and

if

something broke, all braking was lost

·

1967

– New Law, must have a dual reservoir or tandem brakes

which would insure that there would be ˝ the system if a hose broke.

FMVSS# - FEDERAL MOTOR VEHICLE

SAFETY STANDARD

·

“Brake

Bias” – because of

weight transfer, favoring one set of brakes over another

·

To

minimize rear wheel lockup

·

Problem

with just having front brakes

·

Past

bias was more like 60/40, now might be more like 80/20 or even 90/10 with the

shorter wheel base cars, These systems

are really like having two master cylinders, one part for half of the system

and one for the other half

·

Diagonal

split, 4 lines from master cylinder, if a rubber brake

hose broke, you would still have one front and one rear wheel braking which

gives even more controlled braking.

minimize rear wheel lockup lock up brakes in rear, you lose control

Diagonal

Base

brakes/Foundation brakes

–

Anti-Lock

Brakes –

Ways

to minimize rear wheel lock up? (to change to proper brake bias)

1. Size of calipers or cylinders

2. Size of Friction material

3. Hydraulic Valving

4. Brake design – disc/duo servo/non servo

(servo =less braking)

5. Size of the drum – bigger drum = more

leverage

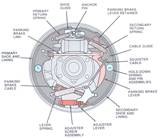

Duo

Servo – has a wheel

adjuster (opposite of cylinder), will float a little; has cylinder and pivot at

top with star wheel at opposite side – servo action in forward or reverse

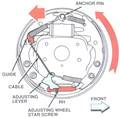

Non

Servo - a wheel adjuster next to cylinder, block at

bottom; cylinder and anchor block at opposite end – star wheel is next to

cylinder

Duo Servo

Servo – applies pressure to something else

Servo action - .030” clearance between drum and shoe,

force of one shoe pushes on the star wheel adjuster to the other shoe

Example: primary shoe – provides

some braking but also forces secondary shoe to brake

Self energizing – the rotation of the drum improves the

friction

Example: wedging action tries to

pull itself in making it more effective (pg.90)

Move

out at top, away from anchor pin

Move

out at top, away from anchor pin

How

does self-adjuster work? When you are in

reverse and stop, why don’t they keep adjusting?

Non

Servo –Leading/Trailing

·

Less

efficient than duo server

·

Has

leading (front) – trailing (back)

·

Chances

are sizes are identical

·

Shoes

must come back to anchor pin – IF NOT,

SOMETHING IS WRONG!

·

Strut

rod on wrong, parking brake not releasing

·

This

can cause lock-up on that wheel, it gets a “head start” on braking

Hydro boost –Brake power assist that runs off power

steering pump

·

Hydraulic

lines from power steering to unit behind the master cylinder

|

Duo Servo |

I.D. |

|

Primary |

Secondary |

|

Edge brand: PRI |

SEC brand |

|

Smaller |

Larger |

|

Front of vehicle |

To rear of car |

|

Lighter in color |

Darker in color |

|

Less coefficient of

friction |

Higher COF |

If

you get these backwards; will still work, but will make a difference in inches.

Hubless Drum

1.

Centering cone on spring, aligning cup in lathe

2. Put hub on

3. Another aligning cup

4. Spacer – to equalize pressure

5. Nut/spacer combo

6. Machine tight together, less vibration

7. Push rod back in corner of hub

8. Put equalizer on top, turn knob in and out a little

9. Vibration dampener on hub

10. Step, stop lathe

Rough cut – 20 speed

·

Scratch

test, bit makes contact with drum - if

constant noise, OK

·

If

on/off noise – turn 1/2, moves in 1/2 inch

·

If 2

scratches are side by side – drum has high/low spot

- preferred scenario

·

If

in opposite sides – our mounting is wrong

Take

off at least .005” – each line is .002” = 2 1/2 lines

Herringbone

pattern – caused by not

installing vibration

Dampener – the leather belt

NOTE:

·

Don’t

machine if you don’t have a problem

·

Book

recommends only if at least a .015” - .020” groove

Machining

Drums

Cut

off as little as possible, but never less than .005”

A = depth of cut “5 to 20”

Start at B (on the closed

end) and move to C

Feed rate – how fast

you go from B to C

|

|

|

Depth |

Rate |

|

Optional

|

Rough

Cut |

.005” |

20

- .020” every rotation |

|

Required |

Finish

Cut |

.005” |

5 - .005”every revolution |

If

you cut too small an amount, the bit will float because it can’t dig in and

also because the chip of metal will be too small and will not dissipate

heat ______

A

brake lathe can be radius graduated or diameter graduated.

Radius

graduated – if turn dial

@ .004”, actually cutting .008” off of drum (double)

Diameter

graduated – if at .004

is .004, what you see is what you get

Amoco lathes are all

diameter graduated.

Some

rotors have a cooling groove.

LAB

DEMO – HUBBED ROTOR ON LATHE

1. Tapered adapter mounts inside - duplicates the plane of rotation

2. Equalizer

and 2 tapered adapters

3. Nut/spacer combo

4. Vibration dampener – [vented hub/lead

weights]

5. Uses cutting arm

6. Make sure you cut right up next to hat

7. Move knob in until you make contact

·

Adjust

sleeve to.0

·

Each

line is .002”

8. Spaces high/low high is for rough-cut,

towards machine _________________

9. Cut .005” off each side to take care of most

rotors (slow cut)

·

Minimum

is .003” off each side

[Can

rotate bits 3 times in each side, 6 rotations total]

10. After satisfied with cut, put a non

directional finish

·

A

Directional finish creates a noise – susceptible to frequency

·

Use

sandpaper, move back and forth as it turns

·

DA Sander/

lasts longer, tilt this way

·

Has

a plastic gear – “weak link”

11. When runs to end, there is a brass sleeve

will run off end of threads and won’t move anymore; it must jump back on, don’t

force

LAB

DEMO – Free Floating Axle

·

94

pre hubbed drum, drum has bearings

1. Take bolts off

2. Opposite side is lower, lube leaks to other

side

3. If nuts inside come loose, the dual wheels

can come out

4. Bolts – 1 for adjustment, 1 to lock up

It

is a good idea to replace seals anytime you do a brake job on a floating

rear axle.

·

If

it leaks, oil will get on brake shoes.

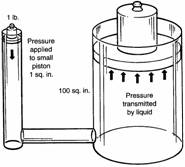

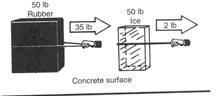

Pascal’s

Law

1. Cannot compress fluid

2. Fluid will take shop of the container

3. Pressure will be exerted in all directions

equally

[

Force

= P*A lbs.

Area = F/P

in2

Pressure

= F/A psi

Strength vs

Speed

Strength vs

Speed

Force

= multiplier

Movements

= divides

·

Pump

brake pedal before you move it out of stall

·

Pads

must have contact with rotor

What

provides the small amount of clearance between pad and rotor:

1.

Rotor run out

2. Action of the square cut seal

Lower

brake pedal = Loose wheel bearings

Disc

Brakes:

1.

Self cleaning

2. Less Parts

3. Self adjusting

4. Run cooler

5. Less efficient, require more force

How

disc brakes are self adjusting?

·

The

master cylinder must be able to push piston out farther than the square cut

seal can move

What

can cause a low brake pedal?

·

Loose

wheel bearings

Input

– master cylinder

·

Having

larger area at caliper makes it stronger, but a slower apply

Having

larger area at caliper makes it stronger, but a slower apply

How

much force at master cylinder?

·

Hydraulic

pressure is constant through whole thing

Area

of a Circle

.785 x (diameter)2

Must convert to square inches:

Example = 3” diameter piston

.785 x (3)2 =

7.065 in2

Curved piston = to get more surface area.