Steering and Suspension

S.A.I.

– Steering Axis Inclination

1.

Typical 5° - 8° on

2.

Typical 9° – 15° SAI on MacPherson

3.

Not a tire wearing angle

4.

Tilting of steering axis compared to true vertical

5.

Not adjustable – built into steering knuckle

6.

Provides for steering wheel returnability

Example: A car has maximum caster.

Added SAI,

so it has added returnability and no tire wear.

·

A tech notices caster is nonadjustable. Why is caster

Not as

important as it used to be? Because of added SAI

provides steering wheel returnability.

·

SAI lifts the car as you turn either direction.

MACPHERSON STRUTS

·

Replace bearings

·

Replace upper strut busing (possibly)

·

Usually just replace struts – reuse springs/coil

- Look for

oil

- Recommend

gas filled strut , helps ride feel

·

Put in spring compressor to loosen nut at top

- Mark when

you remove

·

May be able to buy cartridge to rebuild strut.

·

Tubing cutting – muffler tool – strut tool

·

Oil in, leave room for expansion

Terms: Alignment Equipment

Vernier caliper - specs

Tread depth gauge - video - guidelines

Flare nut wrench Valves as hydraulic brake system

Helicoil

Battery charging

Thread pitch gauge Composite, hubed, hubless rotor

Hand impact driver

Toe adjustment

LAB PRACTICAL

·

5 Minutes per station, 11 stations

·

Measure 3 drums

·

Measure rotors

·

Install drum on lathe – can you do it? Yes or no.

·

Vin – build date, assembly plant location, etc…find

info about vehicle

·

Drums set up – shoes which way on duo servo?

(Primary to

front; secondary to back; non servo, servo)

·

Identify steering arm and any steering linkage

TOE

·

A horizontal line through tire centerline

·

Last adjustment to be made

•Greatest

tire wearing angle

•The

distance between the front of the tires compared to the distance between the

rear of the

same tires.

•Parallel =

“0”

•Toe “in”

equals Positive

•Total Toe

(sum toe)

•Individual

Toe, compare toe of one tire to imaginary centerline of vehicle

•Toe can be

measured in DEGREES, or INCHES, or MILLIMETERS

•Measurement

in inches or millimeters consists of the difference between the front and the

rear of the tires

•When measured

in degrees, it is the difference between the vehicle centerline and the wheels

true plane of rotation or centerline.

• .125

(1/8th inch) off scuffs a tire 11 ft. sideways per mile (depends on tire

diameter)

Excessive

toe-in (positive) will scuff the outside of the tire

Excessive

toe-out (negative) will scuff the inside of the tire

The

sidewall flexes in the direction of the toe setting

NOTE Common wear with bias ply tires

indicate a saw tooth pattern

3 reasons for a straight steering wheel:

·

Psychological

·

Center to center travel of gear box

·

Proper turn signal cancellation

To straighten steering wheel, put on alignment

equipment, adjust tire rod ends, lengthen one, shorten other.

Turn signals – tabs built under steering wheel actually

cancel turn signals operation. If wheel

isn’t straight, premature or no cancellation will occur

The Ackerman Principle or Toe out on turns (TOOT)

is necessary because the inner wheels turn at a sharper radius than the outer

wheels

•

Provided by

angled steering arms

Adjust wheels evenly

to left or to right.

Low side turn – whichever side is lower, which

wheels are straight is the way the tires need to be turned.

TOOT – Toe Out On Turns

·

Front wheels toe out during turns

·

Inside wheel will turn sharper – this is to minimize

tire scrub during turns

·

Aka turning radius

·

2 Types

1. Symmetrical

2. Non-symmetrical

·

Because of offset engines

·

To minimize torque steer – pull during acceleration

·

Won’t see often

·

As you turn, the angle between the steering arm and inner

tie rod en becomes less, straightens out

·

Angled steering arm – What

physical part provides for TOOT? Angled steering arm.

Steering arm – connects to inner tie rod and part of

knuckle.

Springs – 3 types:

1. 1. Leaf Spring – bends, flexes

2. Coil – compresses

3. Torsion Bar

– twists

Torsion Bar – can be longitudinal or transverse

(side to side)

·

One advantage, it is adjustable by torquing down on the bolt, torques bar up more

·

Do not want to interchange from side-to-side

Leaf Spring – main leaf with eyelet

·

Shackle allows

leaf spring to change length or

Straighten

out during jounce and rebound

·

Multi-leaf – connected with center tie bolt, holds leaves together;

Locate

where rear end should be

Biggest reason tie bolt breaks is improper tightening of

U-bolts.

·

Avoid removing main leaf [Drawing]

·

When measuring, measure from hole

·

Don’t heat up – changes temper of steel

·

Tie bolts come longer, put nut on before you cut, but

on springs first

SPRING

·

Spring rate – how much force it takes to compress

spring ONE inch

·

2 Types::

1. Constant

rate – stays the same

2. Variable

rate – initial rate is low, but as it is compressed more, it becomes stiffer

Aka – cargo

coil

·

Convolutions or rings of a spring:

- If convolutions are same – constant

- If vary in distance – variable

·

To raise a car with leaf springs:

1. Extend

shackles

2. Add new

leafs – which will provide a rougher ride

·

Springs

1. New Springs

2. Spring

expanders – only but 2 in. within 45° of spindle

They are to

be mounted on 2 separate convolutions

CAMBER

•Tire

wearing angle

•Inward and

outward tilt of the tires

•Negative

when the top is tilted “in”

•0 degrees

when vertical

•Typical

ranges from 1/4 to 1/2 degree positive

Positive camber provides directional stability

•Projects

vehicle weight to inner wheel bearing, which decreases lever effect of the

spindle

Negative camber projects vehicle weight away from the inner wheel bearing

•This

decreases directional stability

•Results in

excessive road shock and a reduction in ride quality

CASTER

1.

Returnability

2.

Directional Stability

·

Normally specified positive, extensive because skinny

·

Frame angle

+ Frame

angle – higher in back

- Frame angle – higher in front

·

Manual – lower caster spec.

·

Power Steering – higher power steering

TURNING ANGLES

20deg. inside wheel and 18deg. Outside wheel

shows 1 1/2° difference

SAI – Returnability – directional

stability, enhanced road isolation

Spindle Arc –

SAI+ camber = included angle (IA)

front wheels be straight ahead prior to

measurement for accurate results

3 Alignment Types

·

Geometric centerline – obsolete

·

Thrustline – non adjustable rear suspension

·

Total 4 wheel alignment – adjustable rear suspension

NEGATIVE

Thrust Angle

Set-back - as close to 0 as possible on front wheel –

is farther back than other or forward

- right wheel to back –

positive setback ; will effect caster

RACK AND PINION

Never replace

with original equipment.

Rack - flat gear

Pinion – round gear

·

Has a torsion bar – only common link between steering

wheel and tires

- Built

into spool valve – rises need for assist

- Senses

how much resistance at tires during turning

·

In cold weather square cut seals may push to outside

– high pressure

- Will

start to wear soft aluminum inside housing

·

Can buy long or short – with or without tie rods,

etc.

·

Inner and outer tie rod ends

POWER STEERING

·

If you have problem with power steering, check belt

tension

·

Pump can put out 0-1400 psi, (All are approximate

pressures)

Idle = 100

psi

Highway

Driving while turning = 200 psi required

Parallel

Parking = 500-600 psi required

·

Power steering fluid has higher temp and pressure

rating than transmission fluid

Clockspring

·

Don’t wind up too tight

·

For airbag

·

So, don’t turn steering wheel when removing a rack

and pinion

Electrical Switch in Power Steering Circuit – pressure

switch, opens up circuit to AC air compressor at maximum pressure

Stabilizer Link –New style that can be damaged by

spinning with air tools:

Example

Intrepid, Toyota

·

Some are not interchangeable

·

Can make noise

Coil Springs and Stabilizer Bars

·

Smaller springs will have more body roll

·

The smaller coil springs, the bigger the stabilizer

bar

Sector Lash Adjustment (Gear Box)

3.

Sector shaft – changes rotary motion to reciprocating

motion

- Teeth on second gear are tapered

- Teeth mesh with recirculating ball

nut

·

Tapered – so when you

move shaft up, there is more clearance;

- Move shaft down, less clearance

- You want some clearance or lash,

only a small amount

·

Procedure: This

is subject to actual manufacturers service

procedures.

·

Straight ahead position (wheels), middle of gear box

is tightest point

·

Loosen lock nut and lightly bottom out shaft and back

it out half a turn

·

Lock it down, test drive to make sure that

there is no binding.

When removing Pitman Arm:

1.

Never hit on sector shaft, or use pickle fork

2.

Sector shaft is tapered

3.

Soft aluminum side cover supports sector

shaft – you could strip threads

4.

Why is a Pitman Arm puller so

short and stout?

It uses brute force twisting motion to separate; other pullers use the

force of the puller plus

hitting it to separate components.

Rack and Pinion Steering Never put any rotational twisting

force on a rack and pinion when removing a tie rod

Flex coupling – acts as a U-joint and to minimize vibrations from

pump to steering wheel.

3. Any

looseness is too much on a rack

4. Considered to

be a weak system – doesn’t have

angles to dissipate movement like a

parallelogram

linkage does and don’t forget inner tie rod

looseness.

·

What looseness we could get by with in the past on

SLA suspensions will cause vibration or shimmy on rack and pinion steering

systems.

RACK

AND PINION- backlash adjustment

5. Adjustment:

1.

Straight ahead position

2.

Loosen lock nut

3. Bottom out adjusting plug lightly- back out ½

turn

(still spring loaded with very little clearance)

If there were

any imperfection in the rack, turning could create a bind or tight spot.

This design

eliminates binding because spring can flex to prevent bind up.

·

In Ford, you take shims out to decrease back lash

Hidden Toe

Change

– toe change due to looseness in suspension while driving. This is caused by loose idler arms and other

looseness. Having two idler arms really

increases toe change.

Purging a Shock – getting air out

·

Expand a few times and compress before you put in a

car

·

Shock absorbers are used to control spring

oscillation and not to support the car.

·

When to replace?

1.

Oil leakage out of shock

2.

Time, lots of miles

3.

If it bounces more than it should (this is

hard to

tell)

·

Consider replacing with gas filled shocks

·

50/50 shock – as hard to pull out as it is to pull in

like used on a steering dampener.

70/30 shock ratio, 1st

number is extension and

second number is rebound. This is by engineering

information. Racetrack guys usually refer to this ratio

backwards from what engineers

do.

70

- Rebound – out or extension of shock.

/ 30

-jounce - in, compression of shock

At the track, a 90/10 shock on the front would allow the

front end to come up easily and go down slower.

Purpose

of SLA: Minimize tire scrub during jounce & rebound. This will allow the camber to change during

jounce and rebound but will minimize side-to-side scrub of the tire during this

movement. The normal or acceptable

camber change is called camber arc and is sometimes

around 1 ½ degrees during jounce and rebound.

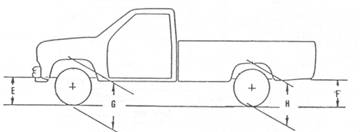

Importance of Proper Ride Height

Ride height measurement is really determining the angle of the suspension

components (like lower control arm position)

Whatever you do to one side of

car, it will try to do the opposite to the other.

- Because of weight transfer

-

Whether side-to-side or front/back

Usually when the driver sits

in the driver’s seat, the left camber will increase and the right camber will decrease.

·

If you do not have proper ride height, you will not be able to

minimize

the tire scrub during jounce and

rebound which is designed into the system at the factory.

·

Lowered or raised suspension will cause the tires to

wear more than they would with proper ride height. This changed condition puts the suspension

(control arms) at different angles and causes the ball joint to travel at

different locations of the arc which causes more side to side movement, thus

more tire wear.

·

Rolling radius –measuring from the middle of tire to

ground. This is used to insure that are

of the same size. This method takes into

consideration the flat spot on the bottom of the tire, which is hard to measure

otherwise.

Some

vehicles

·

Measure ride height – Some systems like the Chevrolet

truck will have the technician measure ride height and compensate with

different caster specs. This allows for

different frame angles because of different loads the truck in subjected

to. As and example, two identical trucks

might be used with different weight in them.

Best

way to Lower Vehicle – drop spindle, which is really a spindle raised

higher on the knuckle. This allows the

control arms to remain at proper angle while changing ride height.

Main purpose

of shock – control spring oscillations; it it does not hold up the

vehicle!

·

The spring of SLA must be stronger than McPherson,

Due to position of spring. The SLA spring is usually located ½ way out

to the ball joint so you could assume the spring needs to be about twice as

strong as the weight at that corner of the vehicle.

·

The smaller the coil spring, the larger the

stabilizer bar is what is usually recommended.

Scrub Radius – distance between 2 lines at the pavement. These two lines are the projected centerline

of the tire (camber) and the steering axis (same as included angle). If they

meet below the pavement, it is called positive scrub radius. If these two lines meet above the pavement,

it is called negative scrub radius. The

actual scrub radius is the distance between these two lines at the pavement.

Scrub Radius on SLA – typically have positive scrub

radius = lines intersect below the surface;

This

tends to toe out

Scrub Radius on McPherson Strut – negative scrub radius

·

Lines intersect above surface

·

Tends to toe in

·

Where the two lines intersect, either above the

pavement or below

·

Uses same 2 projected lines as included angle

·

As long as you have even braking, no problem

·

ABS – one pulses, steering wheel would turn, so they

decreased the scrub radius to minimize steering pull while in abs function. (As

it is pulsating brakes)

·

Deep dish, low profile

Offset wheels and low profile tires

will change the scrub radius

If Scrub radius changes because of different wheel

installed – can’t promise that it will

handle as it was designed.

SAI-

Steering Axis Inclination Typical

SLA - 5°- 8°

McPherson

Strut - 9°

- 15° or more

Is built into the steering knuckle and is not adjustable. Will aid in steering wheel return ability. I considered a non tire-wearing angle. SAI will tend to raise up each side while turning either direction. Increased SAI now does more to help return the steering wheel to straight ahead position so as not to depend on so much positive caster which is a cause of camber roll.